RFID von der SKU bis zum Shop

RFID von der SKU bis zum Shop

Kurze Details:

Die intelligente SKU-Verwaltung wird durch Radiofrequenzidentifikation realisiert(RFID) Technologie. Es gibt hauptsächlich drei Prozesse, um die automatische Überprüfung von der Fabrik bis zur Werkstatt zu realisieren. Es spart viel Zeit und verbessert die hohe Arbeitseffizienz.

Schritte

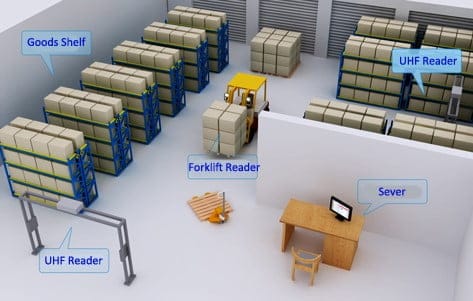

First Process: UHF RFID-Inventarmanagement im Lagerhaus.

1. The administrator write every items’ info into each rfid labels. (For apparel, you can choose the fabric rfid tags for sewing on collars directly)

2. Stick/Install rfid tags on boxes/bags/items.

3. Using handheld rfid reader to scan or read rfid labels for counting and check inventory status.

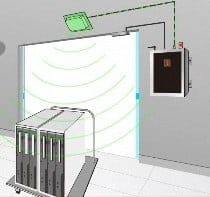

Second Process: Entrance and exit management of the gate in warehouse.

1. Install rfid reader on the forklift(function for searching specified items)

2. Install rfid antenna and reader on the top of gate in warehouse.

3. When the forklift pass through the gate, reader receive labels’ info and transfer to server. (The reader in forklift need to close in case interference between the readers beside gate, simple way is to make an on-off switch to close reader by the trigger mode.)

Third Process: UHF RFID inventory-taking management in shop.

1. When the items that sticking with rfid labels arrived the shop, scan how many itmes come in.

2. For apparel shops, when sorting up to racks, tie up rfid hang tags in every clothes so that it’s easier to make inventory-taking for daily sales volume.

3. Install the rfid gate reader on the shop door for the alarm in case any theft situation.